Education

Make it your story

See how Stronghold transformed the lives of these coffee lovers and make it your story.

ContactNews

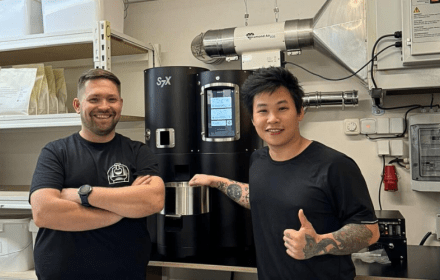

Stronghold in Korbasowy Dwór restaurant

17.04.2025 r.

Stronghold S9X roaster installation in Budapest

11.04.2024 r.

Stronghold S7Pro at Eurogastro and Smakki.

11.04.2024 r.

Coffee acidity - What does it depend on?

24.01.2024 r.

Degrees of coffee roasting

24.01.2024 r.

- 1

- 2